HM Hot Sale HSP Series Coffee and Tea Capsule Filling and Sealing Machine Lavazza Coffee Capsules Production Line,Lavazza Packaging Machine Customized China most popular High speed capsule filling and sealing machine factory offer Online video for your reference: https://youtu.be/MlAAzwVAyMM The...

Send InquiryHM Hot Sale Lavazza Capsule Filling and Sealing Machine with Nitrogen Flushing

Customized China most popular High speed capsule filling and sealing machine factory offer

Online video for your reference:

Brief Instruction:

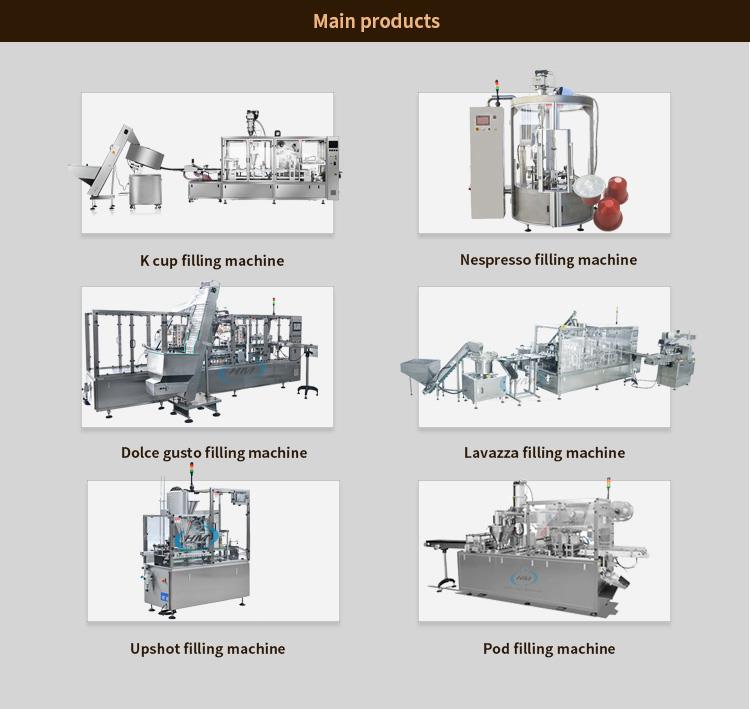

HSP Series Model Coffee Capsule Filling Sealing Machine ( use for Lavazza Point capsule, Kcup, Nespresso, Dolce Gusto etc) is the latest Version Machine, High speed and high quality meet EURO machine standard, this model machine is design specially for Lavazza Point capsule Filling and Sealing. Its material use is better than previous machines; Components use top brand.

* The whole machine stainless steel frame; Organic glass; six columns mould structure; Fixed castor and mobile pulley.

* Photoelectric detection the location of empty capsule storage , If the capsule storage is not enough, machine will alarm to feed Lavazza Point capsule. and machine will automatic stop without capsules,

* Coffee servo screw filling, the filling volume can be adjusted on Touch screen, no cup no filling, lack of coffee in hopper, vacuum feeder automatically open to load coffee into the hoper of machine automatic

.

* Liquid Filling system. (additional function) for fill different flavor into coffee.

* Automatic cutting and sealing filter paper from roll., No cup no cutting and no sealing.

* Twice Sealing, Omron temperature controller to adjust the temperature.

* Automatic mechanical grasp the finished capsules to the conveyor belt. Substandard coffee cup does not grasp and fall into the collection of waste bucket .

Main Working Process:

☆ Special Loading Lanes for capsules

☆Automatic drop empty Lavazza Point to machine

☆Automatic detect whether Lavazza Point well loated on the machine by sensor.

☆Auto Feed the fitler paper roll on the machine

☆Auto cut filter paper from roll paper and welded into inside bottom of Lavazza Point.

☆ Automatic Nitrogen flush

☆ Servo motor to fill coffee while vibrating, weight around 5-20g ( can be adjust), while filling and Nitrogen flush.

☆ Automatic Nitrogen flush

☆Auto cut filter paper from roll paper and sealing on the top of Lavazza Point.

☆ Auto Seal the paper lids

☆ Automatic mechanical grasp the finished product to conveyor ( connect to the conveyor)

☆ Transport to the bag packing machine

☆ Packing in bag

Technical Parameter:

Model | HSP-2 | |

1 | Speed | Over 60-80Cups/min (adjustable) |

2 | Working station | 2lanes |

3 | Filling range | 1-7grams |

4 | Filling accuracy | ±0.05g~±0.1g |

5 | Voltage | 220/380V,50/60HZ, can be custom-made according to customer requirement. |

6 | Air pressure / gas consumption | ≥0.8Mpa/0.1m² |

7 | Working Temperature | 5-35°C |

8 | Relative humidity | ≤85% |

9 | Machine size | L 4800mm* W1000mm* H2550mm |

Why Choose Us

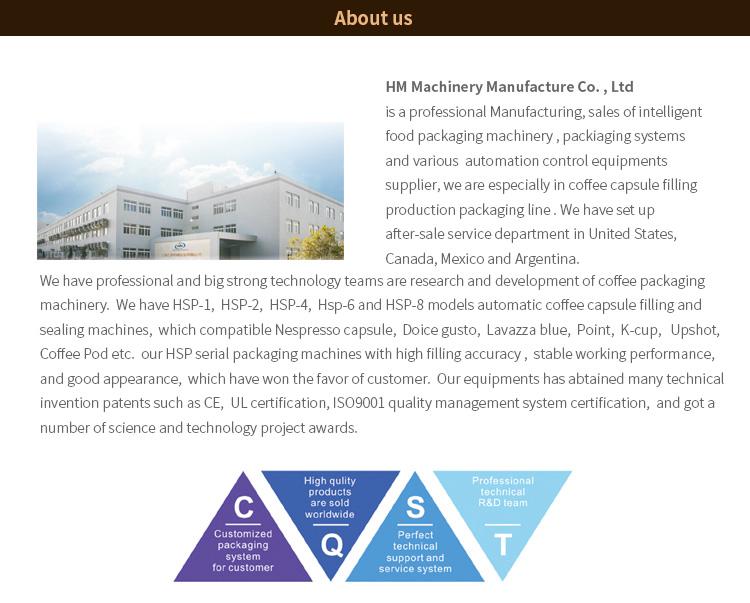

a. We have been in packaing area more than eight years,offer customized packaging system experiencedly.

b. Professional R&D technical team,with high filling accuracy and sealing.

c. Engineer service is available in overseas

d. 12 months warranty

e. 24h online service

f. Europe machine standards,with world famous spare parts

Contact Us

Miss Linda Yan

HM Machinery Manufacture CO.,LTD

Add: No.28,Lane 341,Jiuxin Road, Song jiang, Shanghai , 201615

Factory Add: Kunshan City, Suzhou,Jiangsu, China

Mobile: 0086- 13917470643/13181428178

Tel:0086 (21)-37632096

WhatsApp: +8613917470643

Email: [email protected]

Skype: [email protected]

Website: http://www.coffeemachinessupplier.com or http://www.hmmanufactory.com/