HSP New Technology Lavazza Point Machine Brief Instruction: Lavazza point filling machine ( use for Lavazza point filler and sealer) is the latest Version Lavazza point machine, This model Lavazza point packing machine proves its flexibility being able to get upgraded in speed on the field, from...

Send InquiryHSP New Technology Lavazza Point Machine

Brief Instruction:

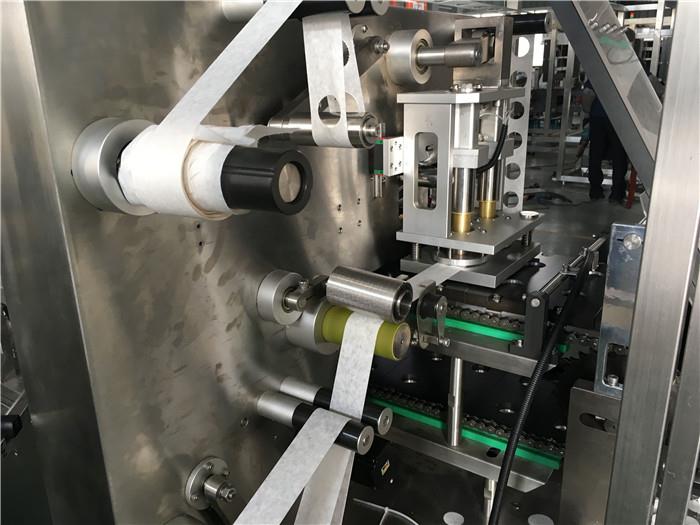

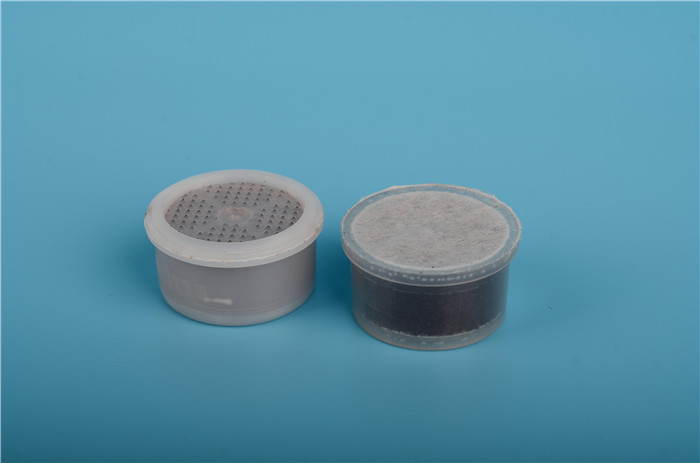

Lavazza point filling machine ( use for Lavazza point filler and sealer) is the latest Version Lavazza point machine,

This model Lavazza point packing machine proves its flexibility being able to get upgraded in speed on the field, from 2-8 production lanes, and fitting different capsule styles on the same machine, with an easy size changeover between the different formats

Advantage:

Extremely precise dosing unit to assure correct product weight

Easy cleaning and product change, even between coffee and soluble powder.

Possibility to handle different capsule styles with easy size changeover.

Aroma doser to drop liquid flavor into the capsules

Upgradable in speed , even on field.

Possible tailor-made solutions according to capsule configuration

Minimal maintenance requirement

Working Process:

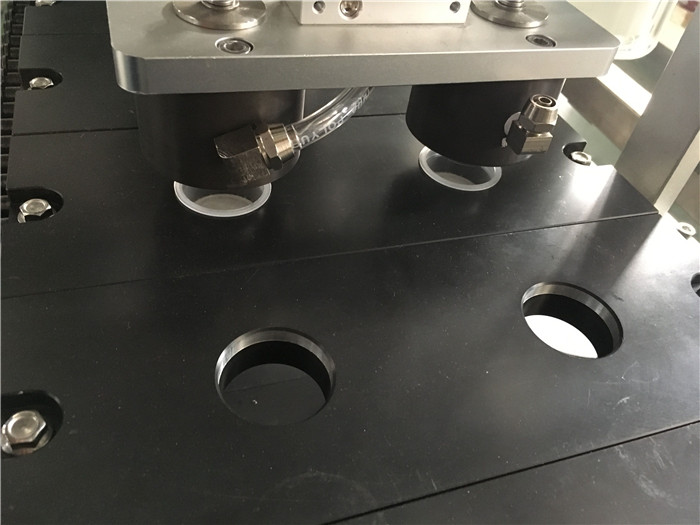

☆Lavazza point capsules feeding unit

☆Automatic drop empty Lavazza Point to machine

☆Auto detect Lavazza Point well loated on the machine

☆Auto Feed the roll-stock paper on the machine

☆Auto cut filter paper from roll paper and welded into inside bottom of Lavazza Point.

☆ Automatic Nitrogen flush

☆ Servo motor to fill coffee weight around 5-20g ( can be adjust), while filling and Nitrogen flush.

☆ Automatic Nitrogen flush

☆Auto cut filter paper from roll paper and sealing on the top of Lavazza Point.

☆ Auto Seal twice

☆ Automatic finished product exit unit to conveyor belt.

Technical Parameter:

NO. | Model | HSP-1/2/4/6 |

1 | capacity | Over1800- 10800Cups/hour |

2 | Working station | 1-6lanes |

3 | Filling range | 5-20grams adjustble |

4 | Filling accuracy | ±1.5% |

5 | Voltage | Three Phase 240V 60HZ |